menuProduct Center

backtrackYour locations:Home → Producs → Automated production line

Description

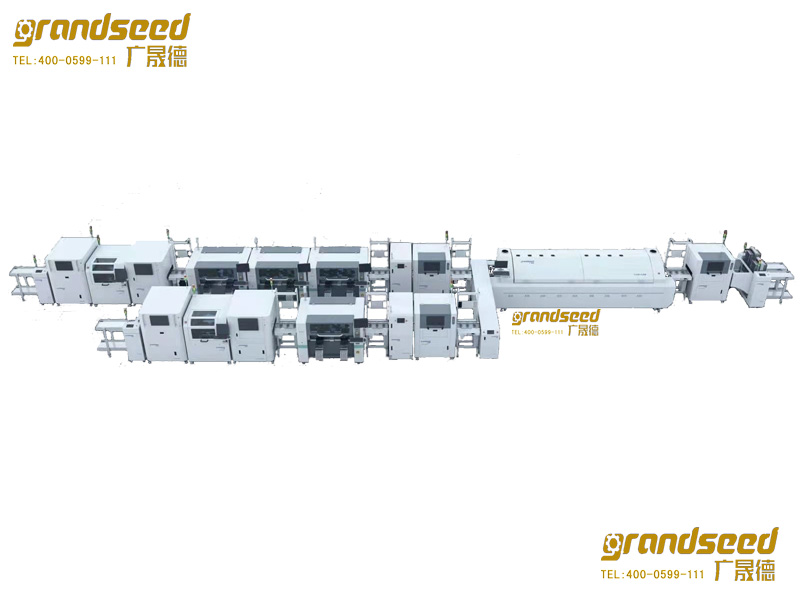

Fully automatic double-layer electronic assembly line working video

Power part configuration of automatic double-layer electronic assembly line

The motor adopts Taiwan Chenggang 2.2KW three-phase motor, WPS 80 type 1:200 reducer, 3HP frequency converter, frequency conversion speed regulation, linear speed 0-2M/min adjustable

Full-automatic double-layer electronic assembly line transmission device

38.1 pitch 17 teeth synchronously rotating sprocket, equipped with φ50mm driving shaft and tensioning mechanism

Body configuration of automatic double-layer electronic assembly line

1. Body and frame: The frame is made of 40×40mm steel pipe welding; the body guard is made of 1.5mm cold plate, and the feet are equipped with galvanized adjustable feet. The height of the working surface is 700±20m adjustable

2. Conveyor chain: use C212 two-inch double-pitch single-lug high-strength double-hole chain produced by Hangzhou Chain Factory.

3. Conveying track: adopt standard 30×30 angle iron to carry.

4. Chain plate: Use 10mm gray PVC board to make specifications: 148×500mm.

5. Working power supply: set on one side of the fuselage, with three strip multi-function sockets (one per 1 meter/work station). The wiring is a 4.0mm stranded copper core wire.

6. Lamp holder: The lamp holder is welded with 40×40mm steel pipe, and the lamp holder is every 2 meters.

7. Lighting: Install 28W energy-saving lamps every 1.5 meters on the lamp stand, and each lamp has its own small switch.

8. Trachea: Set a trachea in the middle of the lamp holder, made of 6-point standard galvanized water pipe, and install a Y-type quick connector every 1 meter.

9. Wind batch hooks: Install wind batch tool hook brackets in the light frame, equipped with tool hook pulleys per meter, a total of 28 left and right in the whole line.

Full-automatic double-layer electronic assembly line body color: electrostatic spray computer white.

400-0599-111

400-0599-111