menuProduct Center

backtrackYour locations:Home → Producs → Automated production line

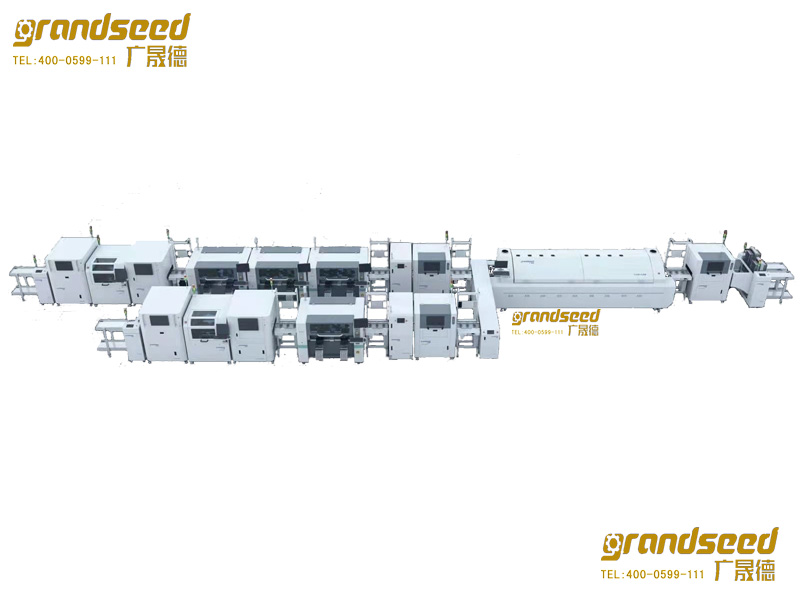

Description

1. Guangshengde l double-layer production line drive system:

1, 2HP motor, gear box: 80 tooth box;

2. Speed: 6m/min, speed of tooling board: 6m/min;

3. The transportation of tooling board adopts RF2060, 3 times speed chain.

2. Double-layer production line fuselage line structure:

1. The bracket adopts a 50mm*50mm*2.0mm square pass, and the height of the working surface: 740±20 mm;

2. Both sides of the wire body are assembled from super-strength 100*118mm triple-speed aluminum profiles;

3. The lighting uses a 28W single T5 energy-saving lamp with a cover, and the lamp holder material uses a 25*50 iron flat pass;

4. Assemble the power supply system, each station is equipped with a double plug-in seat, 1.2 meters per set;

5. Assemble the quick connector air source triple piece 40SM with 20PH quick connector;

6. ??The craft kanban adopts aluminum craft card holder with A4 acrylic board;

7. The wind batch chute is made of 28*35 aluminum.

3. Double-layer production line electric box:

1, using Mitsubishi PLC control;

2, Japan Mitsubishi air switch;

3, OMRON relay.

4. Conductive rails of double-layer production line: integrated conductive rails are installed on both sides of the line body

5. Double-layer production line tooling board:

1, size (500)L*(500)W*(25)Tmm;

2, two are not installed at the bottom of the tooling plate;

3. The tooling board is made of 25mm density board with anti-static rubber, conductive copper strips, T-shaped edging; two sockets are installed at both ends.

5. Delivery deadline: 15 working days for delivery.

6. Packaging method: use protective film_material packaging, the method is determined by Party B.

Seven, delivery method: Free delivery to your company's factory (Shenzhen area).

400-0599-111

400-0599-111