menuProduct Center

backtrackYour locations:Home → Producs → Assembly line

Description

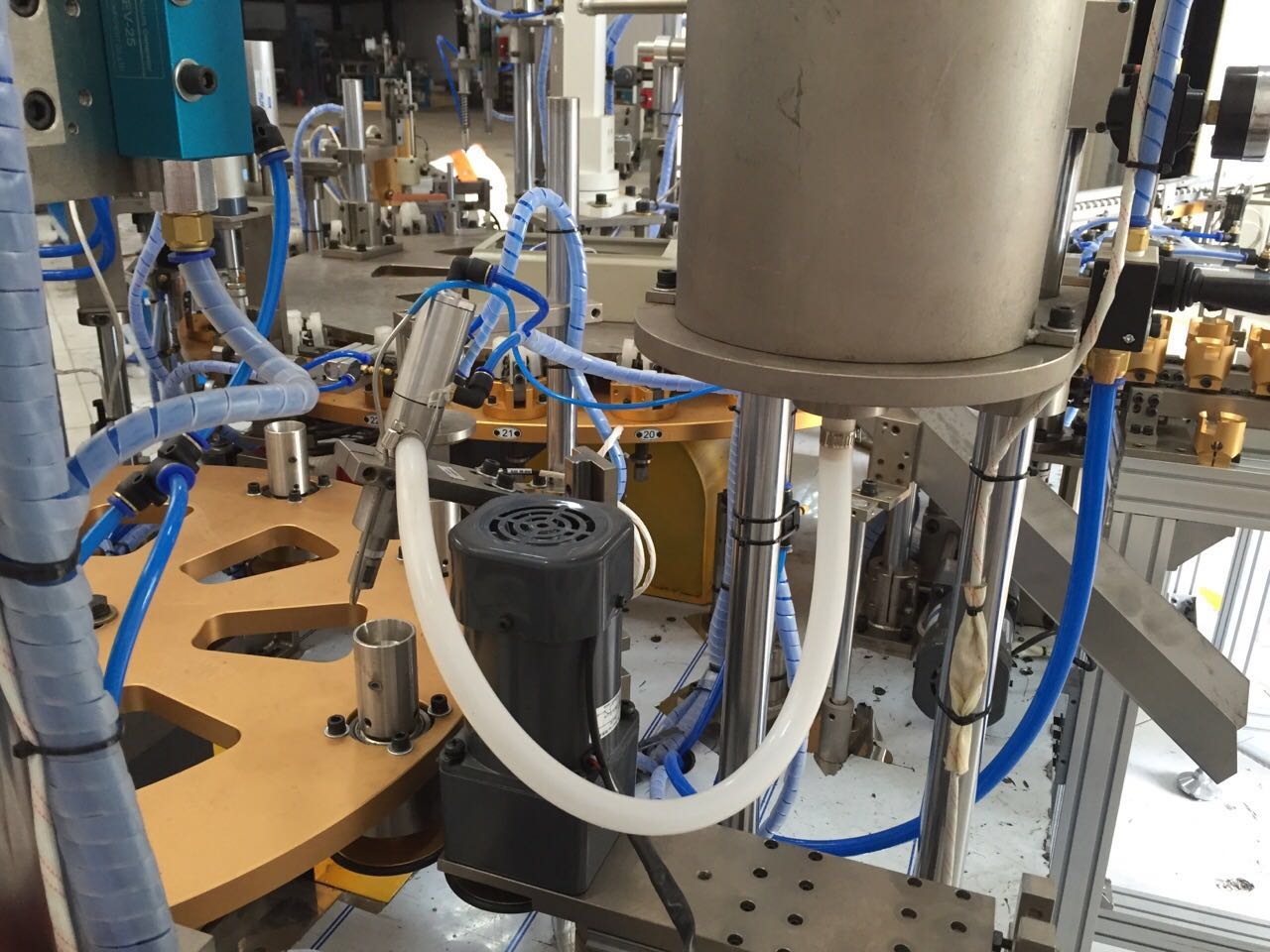

Automatic bulb lamp assembly line

xLED bulb lamp fully automated assembly line configuration

1. One set of 24-station bulb assembly machine for the main body (the equipment process is manually put into the assembled power supply and aluminum substrate on the feeding conveyor belt, the equipment automatically leads the whole line, and automatically installs E26/E27 heads; trimming and bending Wire. Aluminum rivets. Power detection. Pressure needle. Dispensing (8-station split). Buckle blister. The specifications used can be customized according to customer requirements. Generally, the two similar specifications can be used in common (listed as : 7W, 9W, universal), the whole line only needs 2 operators, 1 person for feeding semi-finished products, discharging blister and collecting finished products for packing. At the same time, it can take into account the feeding of other raw materials and 1 person, which can replace 6 people for manual assembly. Production capacity and process quality are stable.

2. Wire size: length 3000mm*width 1800mm*height 1800mm

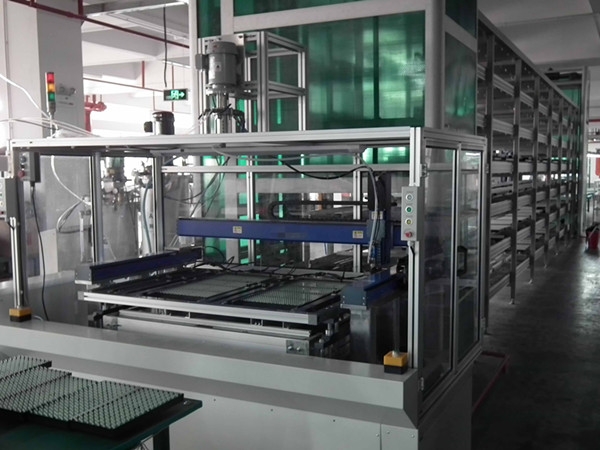

3. One 76-station crawler-type unloading storage chain, and finished lamps off the assembly line;

4. The operating speed of the machine is 1200-1350pcs/hour, and the pass rate is greater than or equal to 95%;

5. Control system: OMRON other components, Omron or its quality equivalent brand;

6. Pneumatic valve adopts safety voltage 24V, main motor 380V, 50HZ; 7. Pipeline gas requirements: high pressure wind 0.5~0.8MPa;

LED bulb lamp automatic assembly line working video

LED bulb lamp fully automated assembly line program video

400-0599-111

400-0599-111