menuProduct Center

backtrackYour locations:Home → Producs → Assembly line

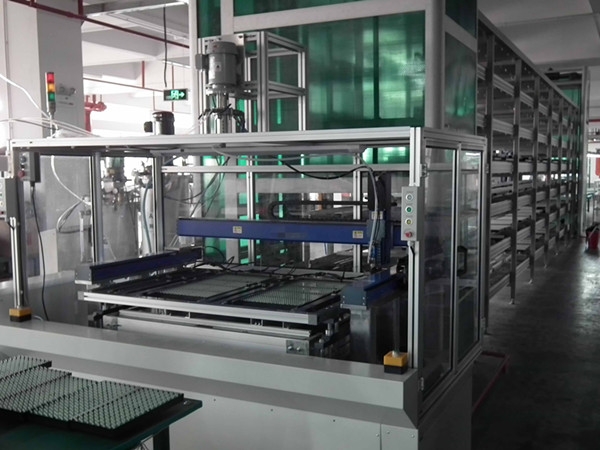

Description

1. Two-row assembly line drive system configuration

1. 1HP Shuangjianglong brand motor, gearbox: Qingfeng brand 70 tooth box; the head and tail are made of square steel, stable, and the motor and motor are not easy to loosen;

2. Speed: 0-6m/min, 1HP frequency converter speed regulation, using frequency conversion speed regulation, safe and low noise;

3. The driving roller is 6 inches*300, and the driven roller is 3 inches*300.

2. Double-row assembly line structure configuration

1. The support is made of 40*40 iron square pass, working surface height: 720±20mm;

2. Standard screw connection, multiple disassembly damage. Easy disassembly and assembly, stable and not deformed;

3. The pull-throughs on both sides of the middle guide rail of the line body are made of aluminum alloy material, assembled from 40*60 aluminum square passes, which are not easy to pollute electronic products;

4. Green Dutch δ2*350PVC transport belt, seamed and connected, the workbench is made of anti-static rubber, the Guangshengde brand can be printed within 2 years;

5. The bottom of the conveyor belt is supported by a galvanized pallet, and each meter has a φ25*350 galvanized pallet to support it, which is not deformed and ensures stable transportation;

7. The assembling power system adopts pvc wire trough, 2.5mm2 power cord, and each station is equipped with multi-hole square socket, 1 per 1 meter;

8. Long workbench specification: 300mm, the table is made of δ16mm wood board, the surface is pasted with green anti-static rubber, semi-circular wood edging;

9. The kanban bracket is made of 20mm*8mm aluminum profile, with an A4 rubber sleeve per station;

10. Install two special air-bearing aluminum materials on the top of the lamp holder, and each station is equipped with a wind-batch car;

11. The width of the instrument panel is 300mm, the table top is made of δ16mm wood board, the surface is pasted with white fireproof board, and the semi-circular wood is edging.

Third, the lighting design of the double-row assembly line

28W/T5 energy-saving lamp with cover, each lamp comes with a small control switch. Use a photometer to test the brightness of 369 Lux in the same environment. The two sides are filled continuously, and the lamp pass material is 25*50 iron flat pass.

Example: A 15-meter belt line (compared to fluorescent lamps), with 27 lamps installed on both sides, calculated according to the annual power consumption of the 22-day, 8-hour work system (27 lamps * 28 watts * 8 hours * 22 days * 12 Month = 1596 kilowatts) energy-saving, power-saving, can save 456 kWh, an average of 25.3 kWh per lamp per year

400-0599-111

400-0599-111