menuProduct Center

backtrackYour locations:Home → Producs → Drying line

Description

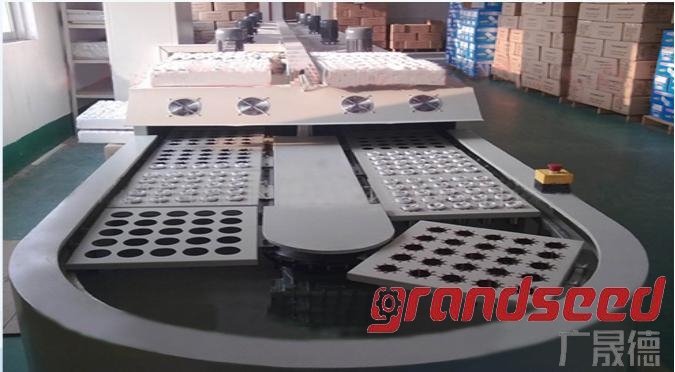

LED display drying line configuration instructions

1. Power mechanism: Taiwan TECO Motor P=1HP, Taiwan Chengda reducer

2. Tensioning mechanism: self-made parts by our factory

3. Line body: 917, 918 high-quality aluminum, Ningbo triple-number special chain, bracket 60/60 square pass production, computer color paint, the middle layer is a rework line.

4. Air circuit: 6 points standard air pipe, including three-way elbow.

5. Air source triplet: Taiwan Shannais brand

6. Blocker: Produce high-quality QX-IV horizontal special blocker, blocker Produce high-quality QX-3 vertical special blocker

7. Transition section of upper and lower parts: P=60W Korean electric motor drives anti-skid belt

8. Upper and lower elevators: Taiwan Kun brake motor realizes up and down lifting, 60W Panasonic pallet motor realizes the moving in and out of the product tooling board, and the outer enclosure is made of high-quality sunshine board and aluminum profile edging parts.

9. Tooling board: The self-made special tooling board is made of a toughened glass board and a tooling fixture made of 4 pieces of aluminum profiles to ensure the surface level of the tooling board, which is not easy to be deformed and easy to clean. Specification: 750*1100mm

X. Electronic control: The key components are imported from Japan, Omron limit switch, Spinner relay, Chint air switch, Mitsubishi PLC and touch screen

400-0599-111

400-0599-111